Simulation of Cavitating Flows

Stream can be used to simulate flows with cavitation by loading the

cavitation module at run-time. This is done by inserting the following

loadModule directive into the run control file as shown below.

loadModule: cavitation_nist

{

... standard run control file content

}

The cavitation_nist module uses tabulated REFPROP data for the

equation of state and the fluid transport properties. The following

sections discuss the analytical models for the cavitation source terms

and provide information on the run control file variables required to

perform simulations with the cavitation module.

Cavitation Model

Stream uses a homogeneous equilibrium model (HEM) to simulate the onset and evolution of cavitation within the fluid system. With such a model, the phases in the system (liquid, vapor, and non-condensable gas) are spatially averaged and assumed to occupy the same volume (homogeneously mixed). In addition, all phases are assumed to be in both mechanical and thermodynamic equilibrium, whereby the pressure, temperature, and velocity of the phases at any point are identical. The HEM is considered a good approximation for cavitating flows where the disturbance time scales and frequencies are long compared to the cavitation equilibration time. With these approximations, the continuity, momentum, and energy equations are solved for the mixture, rather than for the individual constituents of the flow. In addition, a transport equation for the vapor mass fraction is solved which contains source terms which generate vapor when the local flow pressure becomes lower than the vapor pressure of the fluid at the local temperature. A transport equation is also solved for the non-condensable gas (NCG) mass fraction. The transport equations for these two quantities are shown below:

where \(\rho\) is the mixture density, \(v_j\) is the flow velocity, P is the static pressure, T is the temperature, \(\alpha_V\) is the vapor mass fraction, and \(\alpha_{NCG}\) is the non-condensable mass fraction . The following subsections describe the models that are available for the net vapor production rate source term \(S(P, P_{vap}(T))\) and the source term scaling factor \(F(P, P_{\min}, F_{\max}, n)\), which is can be activated in certain instances to prevent flow pressures from reaching unphysically low values.

Merkle Source Term Model

The Merkle source term model [MeFB1998] [HoAU2007] is a simple heuristic model in which the net vapor production rate is linearly proportional to the difference between the local flow pressure and the local vapor pressure. The expression for the net vapor production rate is given by the following:

where \(\rho\) is the mixture density, \(\alpha_L\) is the liquid mass fraction, and \(\alpha_V\) is the vapor mass fraction. The forward production and backward destruction rate coefficients \(K_f\) and \(K_b\) are given by:

In the expressions above, \(\tau_{vap}\) is the vaporization rate constant, \(\tau_{cond}\) is the condensation rate constant, and \(\rho_{\infty}\), \(U_{\infty}\), and \(L_{\infty}\) represent the freestream fluid density, velocity, and the reference length scale, respectively. These parameters can be specified in the run control file using the names shown in the table below.

Variable |

Description |

Default Value |

|---|---|---|

|

Vaporization rate constant |

1 |

|

Condensation rate constant |

0.0125 |

|

Reference Length |

None |

|

Reference Velocity |

None |

|

Reference density |

None |

The Merkle model can be selected by specifying source=Merkle in the cavitationEquationOptions variable

as shown below.

cavitationEquationOptions: <linearSolver=SGS, relaxationFactor=0.9, maxIterations=5, source=Merkle>

The corresponding parameters for the model can then be set using the MerkleSourceParameters variable as follows.

MerkleSourceParameters: <tauVap=1.0, tauCond=0.0125, L=0.7, V=1.5, rho=1.15>

Zwart Source Term Model

The functional form of the Zwart source term model [GeZB2004] is derived from the Rayleigh-Plesset equation which describes the growth or collapse of a vapor bubble in a pressurized fluid environment. Although more formally based on the physics of nucleation and vaporization, this model is none-the-less also ultimately heuristic in nature due to the introduction of constants that allow tuning of the vaporization and condensation rates for the problem of interest. The net vapor production rate is given by the following:

where P is the local pressure, \(P_{vap}\) is the local vapor pressure, \(\alpha_V\) is the local vapor mass fraction, \(\rho_V\) is the local vapor density, \(\rho_L\) is liquid density, \(R_B\) is the bubble nucleation radius, and \(r_{nuc}\) is the nucleation volume fraction. The table below shows the default values for the user-tunable parameters for the model. Generally, unless specific knowledge is available regarding nucleation for a particular problem, one should only adjust the rate constants \(F_{vap}\) and \(F_{cond}\) to tune the model.

Variable |

Description |

Default Value |

|---|---|---|

|

Vaporization rate constant |

50 |

|

Condensation rate constant |

0.01 |

|

Bubble nucleation radius |

1.0e-06 |

|

Nucleation volume fraction |

5.0e-04 |

Sauer-Schnerr Source Term Model

The Sauer-Schnerr source term model [ScSS2008] is based on the Rayleigh-Plesset bubble dynamics equation. The expression for the net vapor production rate is given by the following:

Where \(\rho_L\) is the liquid density, \(\rho_V\) is the vapor density, \(\rho_m\) is the mixture density, \(\alpha_V\) is the vapor mass fraction, and \(R_B\) is the bubble radius. The bubble radius has the following definition.

Where n is the bubble number density, and often takes a value around 1e+08. The table below describes the user tunable parameter for the model.

Variable |

Description |

Default Value |

|---|---|---|

|

Nucleation radius |

1.0e-5 |

|

Bubble number density |

None |

Source Term Scaling Factor

From the description of the source term models above, one can see that a specific functional relationship between the vapor production rate and the difference between the local flow pressure and the local vapor pressure is postulated. For the Merkle model a linear dependence is assumed while for the Zwart and Sauer-Schnerr models a square root dependence is assumed. For certain flow problems, the nature of the cavitation is such that neither functional dependence can provide an ample amount of vapor generation in certain regions without the pressure decreasing to values significantly below the vapor pressure and in certain cases becoming negative. This can result in the demise of the simulation. In practice, in any real device in which the flow is cavitating, the minimum pressure in the domain should remain in the vicinity of the local vapor pressure. In order that this can be achieved in numerical simulations without having to adjust the vaporization rate parameters to unrealistically high values (which would thus cause large amounts of vapor to be produced at all cells where \(P<P_{vap}\)), a source term scaling factor has been included in the formulation. This factor is only applied to locations in the domain where the pressure departs significantly from the local vapor pressure. The source term scaling factor \(F(P,P_{min},F_{max},n)\) is defined by the following expression:

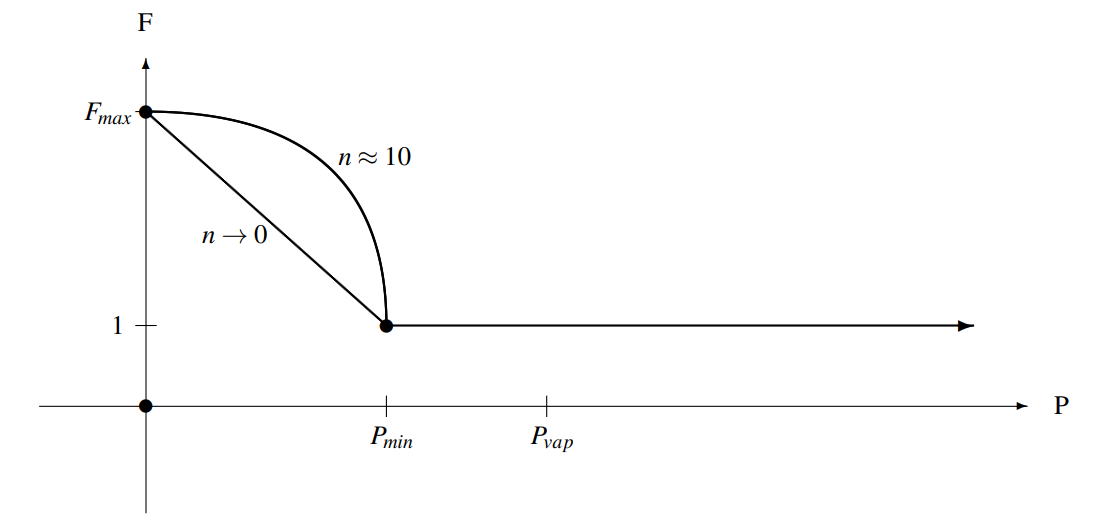

The image below shows a plot of the function, while the table shows the default values the scaling factor parameters. Since the primary goal is

to prevent the simulation from departing too far at any point from the local vapor pressure, the model should have its parameters set such that

below the value \(P=P_{min}\) the source term scaling factor ramps up rapidly. This is achieved typically with the default value of n.

Source term scaling factor for controlling minimum simulation pressure. Scaling becomes active at user specified value of \(P_{min}\). User specified value \(F_{max}\) controls maximum scaling, while user specified exponent \(n\) adjusts the scaling profile.

Variable |

Description |

Default Value |

|---|---|---|

|

Maximum scaling factor |

1 |

|

Exponent |

1 |

|

Scaling activation pressure |

1 |

The maximum scaling factor \(F_{max}\) is usually problem dependent, however, the value in the table is a good starting point. The selection of \(P_{min}\) should be guided by actual experimental measurements on similar flow configurations if possible, however, if such information is not available, values in the range of no more than several hundred Pascals below the vapor pressure are recommended. In general, it is noted that the minimum simulation pressure will be somewhat below the specified value of \(P_{min}\) because this is merely the point at which the source term scaling is activated.

Control File Setup

Setting up a run control file for the simulation of a cavitating flow is like setting up a standard compressible flow problem. It is important to note that cavitating flows can only be simulated in compressible mode. A few important guidelines must be observed when setting up the run control file for a cavitation simulation:

Boundary conditions must be set for the vapor mass fraction variable

vapor_yand non-condensable gas mass fraction variable,NCG_y, on all inlet boundaries.Initial conditions must be set for

vapor_yandNCG_y.The temperature form of the energy equation must be used by specifying

form=temperaturein the variableenergyEquationOptions. The total enthalpy and total energy forms of the energy equation are not supported.

The specifications for vapor_y and NCG_y must always be provided. If there is no NCG in the flow, specify a value of 0. The following

subsections detail each section of the run control file.

Boundary Conditions

Because cavitating flows must be simulated using compressible mode, the only inlet boundary conditions that should be in use are subsonicInlet,

supersonicInlet, and inflow. The following shows an example of the specification of the vapor_y and NCG_y boundary condition

for a subsonic inlet with pure liquid with a small amount of NCG:

Inlet=subsonicInlet(v=10.11 m/s, T=300.0 K, k=0.0, omega=1000.0, vapor_y=0.0, NCG_y=1.0e-06)

Similar specification would be made for the other inlet types.

Initial Conditions

The initial condition for the vapor and NCG mass fractions are set as follows:

initialCondition: <vapor_y=0, NCG_y=0.0, v=10.11 m/s, p=28515.8 Pa, T=300.0 K, k=0.0, omega=1000>

Similar specification of these values can be made using the run control file variables ql and qr or the

variable initialConditionRegions as discussed in the following Appendix.

Equation of State and Transport Properties

The cavitation_nist module utilizes tabulated thermophysical property data from the NIST REFPROP software. A python utility is provided with

the Stream source code that can generate tabulations for liquid, vapor, and saturation data files for any REFPROP species. The utility

will generate three output files with suffixes of .liq, .vap, and .sat. The prefixes for the liquid and vapor files must be

provided using the liquid_model and vapor_model variables in the run control file. The prefix for the saturation file will be taken

from the liquid_model variable. The equation-of-state section in the run control file should look as follows:

liquid_model: NITROGEN

vapor_model: NITROGEN

transport_model: module

Setting the value of the transport_model to module indicates that all transport data is to be obtained from data in the tabulated liquid,

vapor, and saturation files.

Cavitation Equation Options

An example of the cavitation equation section of the run control file with all available options is shown below:

cavitationEquationOptions: <linearSolver=SGS, relaxationFactor=0.9, maxIterations=5,

source=Zwart, vaporProductionRateRelaxationFactor=0.7>

ZwartSourceParameters: <RB=1.0e-06, aNuc=5.0e-04, fVap=50.0, fCond=0.01>

cavitationInviscidFlux: SOU

AlphaViscosity: 1.0e-05

liquid_rho: 736

vapor_rho: 17

NCG_rho: 15

cavitation: on

cavitationSourceScaling: <Pmin=3200, Fmax=100, n=10>

turbulentVapourPressureCorrection: on

The .vars file variables used are summarized in the table below.

Parameter |

Description |

|---|---|

|

Artificial viscosity added to vapor and NCG mass fraction transport equations for numerical stability purposes. |

|

Flux scheme used for vapor and NCG transport equations. Supported

values are: |

|

Reference value for liquid-phase density used in normalizing the liquid term in the pressure-correction equation. |

|

Reference value for vapor-phase density used in normalizing the vapor term in the pressure-correction equation. |

|

Reference value for non-condensable-gas density used in normalizing the NCG term in the pressure-correction equation. |

|

Activates the turbulent correction to the vapor pressure. |

The linear solver options are like the other governing equations that have been previously covered. All linear solvers

discussed (here) are supported for the value of linearSolver, however one should rarely need

to use anything other than the SGS solver. Source term model selection is made using either source=Merkle, source=SauerSchnerr, or

source=Zwart. Default parameters for these three models are shown below:

MerkleSourceParameters: <tauVap=1.0, tauCond=0.0125>

ZwartSourceParameters:<RB=1.0e-06, aNuc=5.0e-04, fVap=50.0, fCond=0.01>

SauerSchnerrSourceParameters: <rNuc=3.0e-06, n=4.8e8>

To explicitly turn off the source terms in the vapor mass fraction equation, one can specify cavitation: off in the run control file. The

default value for this variable is on. Parameters for the source scaling model can be specified using the variable cavitationSourceScaling. No

source term scaling will be performed is this variable is not present in the run control file. If the liquid_rho, vapor_rho, and NCG_rho

variables are not included (or are set to -1), the code will use local cell values to normalize the pressure-correction equation at each cell.

Non-Condensable Gas Specification

All cavitation simulations involve NCG terms in the governing equations, even if the user does not use NCG. The default fluid properties used for

the nonCondensableGasProperties variable is air as shown below. To use a different fluid, the user must specify its molar mass m, specific heat

at constant pressure cp, laminar dynamic viscosity mu, and thermal conductivity kcond in the nonCondensableGasProperties variable.

nonCondensableGasProperties: <m=28.9647 g/mol, cp=1005 J/kg/K, mu=1.805e-5 kg/m/s,

kcond=0.02476 W/m/K>

Output Variables

The table below shows additional field variables that are available for output in cavitating flow simulations. Default variables are output automatically and do not need to be specified in the plot_output line in the run control file.

Variable |

Description |

Default |

|---|---|---|

|

Bulk expansion coefficient * temperature |

No |

|

Source term scaling factor |

No |

|

Liquid volume fraction |

No |

|

Liquid mass fraction |

No |

|

NCG volume fraction |

No |

|

NCG mass fraction |

No |

|

NCG mass fraction eq. residual |

No |

|

Vapor pressure |

No |

|

Liquid density |

No |

|

Vapor density |

No |

|

Vapor mass fraction |

No |

|

Vapor volume fraction |

No |

|

Vapor mass fraction eq. residual |

No |

REFPROP Tabulation Utility

The Python REFPROP tabulation utility is located under in the bin/ directory in the source code. The name of the utility is cav_tab_tool.

This tool is for building necessary liquid, vapor, and saturation input files.

The Python tabulation utility has a functionality for

making calls directly to REFPROP 11. This allows for the tool to tabulate as many

pressure levels as the user desires. The user specifies the REFPROP material name, the pressure

range, temperature range, and the number of data points to use over each range. The user can

also pass a flag (--log_p) to uniformly distribute the pressure points in the log-space to ensure

that an equal number of points resolve each pressure decade (this is good for large pressure

ranges).

A set of .liq, .vap, and .sat files are generated by the tool, and these are the inputs used

by the cavitation_nist module in Stream. Sample calls to the utility for the liquid/vapor files and the

saturation files are given below.

There are two modes that the tool can be used in. One is for tabulating properties outside of a two-phase region in the thermodynamic space. The other is for tabulating the saturation curve properties of the liquid and vapor states.

Liquid/Vapor Tabulation

To generate tabulated liquid and vapor files, one should pass the liquidVapor argument to the tabulation tool. The presence of this argument enables a required set of arguments which are described below:

Argument |

Description |

|---|---|

t_min |

The minimum temperature range value |

t_max |

The maximum temperature range value |

num_t |

The number of temperature levels |

p_min |

The minimum pressure range value |

p_max |

The maximum pressure range value |

num_p |

The number of pressure levels |

log_p |

An optional argument that distributes the pressure levels uniformly across the logarithmic space of the pressure range |

If the log_p argument is not provided, a linear tabulation in the

pressure dimension is performed. The logarithmic spacing enabled by the

log_p argument creates a uniform spacing in the logarithmic space. This

type of spacing is useful when there is a large variation in the

pressure range, as a linear tabulation would result in a low resolution

in the low-pressure region of the tabulation. An example command to

generate liquid and vapor tabulation files for nitrogen in the

temperature range of 65K-300K and pressure range of 50kPa-70MPa is shown

below.

<StreamInstallDir>/bin/cav_tab_tool liquidVapor --fluid_name NITROGEN --t_min 65 --t_max 300 --p_min 50000 --p_max 70e6 --log_p --num_p 200 --num_t 200

In the example above, the liquidVapor argument sets the tool into the mode for tabulating

.liq and .vap tables. The fluid_name argument must match an available REFPROP FLD

file in the REFPROP fluid database. The tabulation levels are done at constant pressure, and so

the t_min and t_max arguments are the temperature range over which to tabulate properties.

The p_min and p_max arguments are the inclusive bounds of the pressure range over which you

want to tabulate data. The log_p argument converts the pressure range into a logarithmic range

and distributes points equally in that space and then converts back to pressure levels. This

ensures an equal number of pressure levels per decade of pressure. This is sometimes a desirable

option. The num_p and num_t arguments are the number of pressure levels to tabulate and the

number of temperature levels to tabulate.

Saturation Tabulation

To generate a tabulated saturation file, one should pass the saturation argument to the tabulation tool. The presence of this argument enables a required set of arguments which are described below:

Argument |

Description |

|---|---|

|

The minimum temperature range value |

|

The maximum temperature range value |

|

The number of temperature levels |

An example command to generate a saturation tabulation file for nitrogen in the temperature range of 65K-300K with 150 tabulation points is shown below.

<StreamInstallDir>/bin/cav_tab_tool saturation --fluid_name NITROGEN --t_min 65 --t_max 300 --num_t 150

In the example above, the saturation argument activates the saturation curve tabulation mode

of the script. This mode has fewer arguments than the liquidVapor mode. The temperature

range and number of points to include are the only arguments that are necessary. These

arguments have the same meanings as they do for the liquidVapor mode of the tabulation tool

that was discussed earlier.

Using Cavitation Tabulation Tool

One must have version 11 of the REFPROP software to use the cavitation tabulation tool. A short tutorial on how to install the dependencies for the cavitation tabulation tool is presented below.

Download the REFPROP 11 software using the NIST downloader. This must be done on a Windows machine. The software will be downloaded into a directory named REFPROP.

Copy the REFPROP directory over to a Linux machine. The software can be put in a directory such as

/home/<User>/software/refprop, where<User>would be your username on the machine). Note: do not rename the REFPROP source code directory because that may cause issues. For example, the path should look as follows:/home/<User>/software/refprop/REFPROPCompile a local version of REFPROP on your Linux machine

Do a recursive clone of the following repository:

git clone --recursive https://github.com/usnistgov/REFPROP-cmake.gitGo to the root of the cloned repository:

cd REFPROP-cmakeCreate a build directory:

mkdir buildChange to the build directory:

cd buildRun cmake to configure the build:

cmake .. -DCMAKE_BUILD_TYPE=Release -DREFPROP_FORTRAN_PATH=/home/<User>/software/refprop/REFPROP/FORTRANBuild the project:

cmake --build .

Once the build is complete, a

librefprop.sofile should be found in the build directory. This shared library contains all the REFPROP functions that the Python wrapper will call. Move this file to the REFPROP directory created in step 2.Move the shared library file:

mv librefprop.so /home/<User>/software/refprop/REFPROP

Set the environment variable

RPPREFIXto point to the REFPROP directory that contains the shared library file.Add the following line to your .bashrc file:

export RPPREFIX=/home/<User>/software/refprop/REFPROP.Make sure to source your .bashrc file after adding this line:

source ~/.bashrc.

Clone the REFPROP wrappers directory into the

/home/<User>/software/refpropdirectory using the following command:git clone https://github.com/usnistgov/REFPROP-wrappersCreate a Python3 environment with the REFPROP interface installed. This will provide a portable and dependable Python environment for running the tabulation tool. Go to your

refpropdirectory and follow the steps below:Create a virtual environment:

python3 -m venv refprop-envActivate the environment:

source refprop-env/bin/activateInstall numpy:

pip install numpyNavigate to the REFPROP wrappers directory:

cd /home/<User>/software/refprop/REFPROP-wrappers/wrappers/python/ctypesInstall the python wrapper into the environment:

python setup.py installTo leave the virtual environment type:

deactivate

One you are in the python environment, you can run the tabulation script and it should execute using calls to the REFPROP library.

References

C. L. Merkle, J. Z. Feng and P. E. O. Buelow, “Computational Modeling of the Dynamics of Sheet Cavitation,” in Proceedings of the 3rd International Symposium on Cavitation, Grenoble, France, 1998.

A. Hosangadi, V. Ahuja and R. J. Ungewitter, “Analysis of Thermal Effects in Cavitating Liquid Hydrogen Inducers,” Journal of Propulsion and Power, vol. 23, no. 6, pp. 1225-1234, 2007.

A. G. Gerber, P. J. Zwart and T. Belamri, “A Two-Phase Flow Model for Predicting Cavitation Dynamics,” International Conference on Multiphase Flow, Yokohama, Japan, 2004.

G. H. Schnerr, I. H. Sezal and S. J. Schmidt, “Numerical investigation of three-dimensional cloud cavitation with special emphasis on collapse induced shock dynamics,” Physics of Fluids, vol. 20, 2008.